- 기업명

- 이노메트리

- 등록일

- 2025-10-27

[보도자료] Innometry Expands ESS Battery Inspection Equipment Orders, Benefiting from AI-Driven Surge in Energy Storage Demand

Series of ESS Projects at Home and Abroad; R&D Expansion Enhances Inspection Technology and Strengthens Production and Supply Capabilities

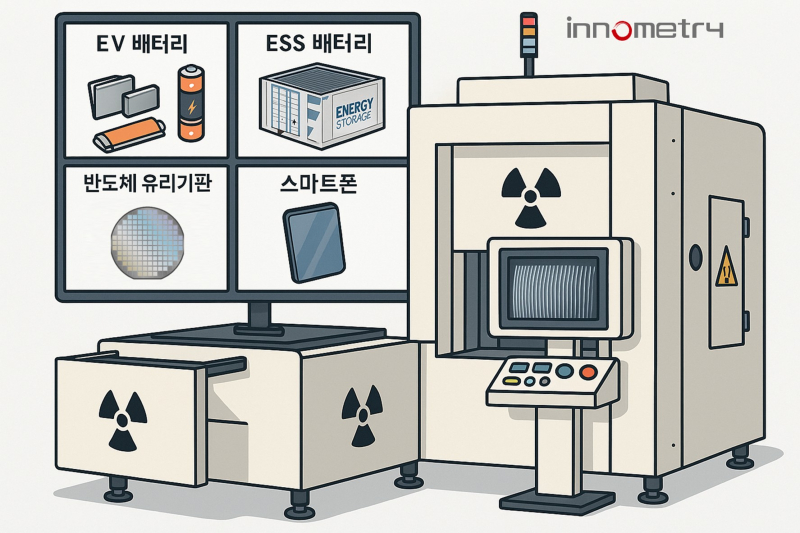

As the Energy Storage System (ESS) battery market accelerates alongside the expansion of AI infrastructure, Innometry Co., Ltd. (CEO Lee Gap-soo), a leading developer of X-ray (CT)–based secondary battery inspection systems, is ramping up supply of specialized inspection equipment for ESS batteries.

The company announced on the 23rd that its domestic and overseas order volume has been rising sharply as key customers accelerate their entry into the ESS battery market.

A company official explained, “The surge in power demand from data centers—driven by AI industry expansion—is fueling ESS market growth. We already have experience delivering a full lineup of CT electrode and gap/foreign-material inspection systems for ESS batteries to major clients, and we are currently in the final contracting stage or have newly launched multiple ESS-related projects.”

Innometry specializes in non-destructive inspection systems that detect microscopic defects inside secondary batteries using X-ray CT imaging. The company is recognized as a market leader, supplying advanced systems to Korea’s top three battery manufacturers as well as major global cell makers.

Recently, battery producers have positioned ESS as a new growth pillar to complement the maturing EV market. Samsung SDI plans to begin ESS battery production in the U.S. in 2026, while LG Energy Solution is adding an ESS-dedicated line at its Polish plant to expand supply for Europe’s power-grid applications. SK On has also signed ESS battery supply contracts and is reportedly converting part of its EV production lines to ESS.

In response to these market trends, Innometry has integrated precision-optical technology with AI-driven software to develop inspection solutions optimized for ESS batteries.

Because ESS cells are typically larger and housed in thicker casings, they require higher X-ray penetration and ultra-precise defect-detection algorithms. In addition, since each customer has different specifications, Innometry has diversified its equipment lineup to deliver optimal inspection quality regardless of form factor or chemical composition.

Given that ESS units must withstand more than ten years of charge–discharge cycles, prismatic cells—which offer better heat dissipation and structural stability—dominate the market. However, some manufacturers are also developing pouch-type ESS solutions.

While LFP (lithium-iron-phosphate) chemistry is emerging as the mainstream choice for safety, lifespan, and cost advantages, NCM/NCA chemistries remain in use for high-power ESS applications.

Kim Young-joo, Head of Business Division at Innometry, stated:

“We are building a comprehensive portfolio and enhancing production and supply capacity to deliver optimized inspection solutions for every type of battery our customers require. Recently, we have expanded R&D investment and secured specialized talent to advance inspection technologies for ESS, LFP, and solid-state batteries. At the same time, we are executing a mid- to long-term roadmap to extend our inspection solutions into new sectors such as semiconductor glass substrates and smartphones.”

이노메트리 IR Page에 접속하시면 다양한 투자 정보를 확인할 수 있습니다.

바로가기 >>

바로가기 >>

본 내용은 기업에 대한 이해 증진을 위한 목적으로, 투자 권유를 목적으로 한 것이 아닙니다.

투자에 관한 결정은 투자자 본인에게 있으며, 회사는 투자에 관해 일체의 책임을 지지 않습니다.

투자에 관한 결정은 투자자 본인에게 있으며, 회사는 투자에 관해 일체의 책임을 지지 않습니다.